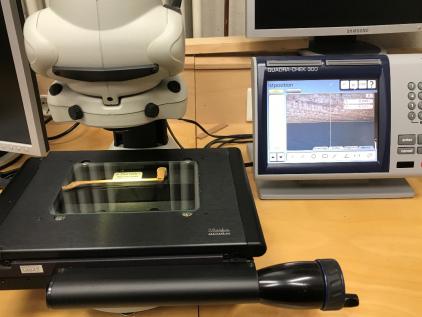

South German (J. A. Stein-circle c. 1780) Detail: hammer shanks

State, proceeding technique

As original material maple could be identified by eye sight .

The original dimensions could be evaluated with micriscope.

The hammer shafts are constantly conical progressing from 3,8 mms in width at the axis to 2,0 mms (bass), decreasing to 1,4 mms (descant) mm at hammer head.

Trace permit a hypothesis about the tools used and the proceedings

(files hand swaged, card scrapers, rasps), here in reducing area

filing traces in the decrease transgression of the shank

progression hypothesis 1:

step 1:

Producing a block from maple in the basic shape of the shanks.

Step 2:

Sawing the single shanks, finishing the single shanks to the individual measures with file and scraper.

result 1:

In principle it might be possible to produce the shanks this way

although it is cumbersome to control the continued shaping of the

shanks.

progression hypothesis 2:

Shaping in a form box; by light shifting alongside a conical groove the size differences of the shank ends from bass to descant can be done in a controlled manner. After the rectangular shaping the edges have just to be roundened and finished with a scraper

result 2:

Shaping in a form box allows a constant sizing and a continuous thinning from bass to descant. The work traces coming with it resemble those found on the parts of the original when the assumed tools (files, rasps, and scrapers) are used.

weitere Arbeitsdetails zum Nachbau des Originalinstrumentes: